.png)

ROTARY 3 STATION TYPE VERTICAL INJECTION MOULDING MACHINE

SV r3

ROTARY 3 STATION TYPE VERTICAL INJECTION MOULDING MACHINE

Rotary 3 station type vertical injection moulding machines are ideal for high production requirements where there are multiple small inserts to be placed in an multicavity mould, reducing the machine idle time while the operator places inserts and removes the finished moulded parts, increasing the production output and efficiency.

The machine is equipped with an 3 station rotary table where 2 operators are required to operate the machine to its full capacity, or a singular automation solution.

ROTARY TABLE

Equipped with an 3 station rotary table, which is electronically controlled, handling 3 bottom half of mould to increase the production efficiency and production output.

ERGONOMIC DESIGN

With the mould moving out of the clamping area both the operators work in the open area where they have full freedom of movement and less stress while unloading finished moulded parts and reloading inserts in mould cavity.

DUAL OPERATOR

This machine requires 2 operator, one at ejection station and second at insert placement station, thus reducing machine idle time and increasing the production output.

RAM TYPE CLAMPING

Clamping unit is equipped with a ram type clamping cylinder which provides fast adn stable clamping pressure, while also being totally maintenance free, providing better control of clamping unit and increased mould safety

SELECTIVE OPERATION

The machine can be operated in 3 station as well as 2 station operation modes depending on your requirements providing multiple operation modes.

ADVANCED CONTROLLER

controllers which are easy to operate while providing advanced features as standard, such as detailed production tracking, machine operational statistics, remote monitoring and control, user profiles, Automation integration, Industry 4.0 devices integration, and much more.

GREENDRIVE

Greendrive hydraulic system is also available, which provides higher machine efficiency, silent machine operation, better accuracy, reduces machine operational temperature, and increases machine's service life.

HIGH PRODUCTION

With 3 stations and 2 operators, the process of ejection and placement of inserts inside the mould cavity becomes very efficient thus increasing production output greatly.

MADE IN INDIA

Designed, engineered and manufactured in India, which translates to better machine quality and higher trust, for customers, it is beneficial due to our big service network, better support, and stronger availability.

INSERT MOULDING

With the vertical design of the machine, it gets really easy to insert mould components as the inserts stay locked in their place and you get perfect insert moulded components.

When it comes to inset moulding Vertical Injection Molding Machines are the ideal choice for many solutions, in the case of overmoulding inserts, precision is a premium. With its compact, design and vertical clamping unit, User-Friendly Controller and easy setup procedure, Rotary 3 station Type Vertical Injection Molding machines can provide the best results for very high volume production requirements.

FAST AND STABLE CLAMPING PRESSURE

All Rotary type vertical injection moulding machines use the ram-type clamping unit.

There are significant advantages of the ram-type clamping unit over the conventional toggle-type clamping unit, such as

-

No extra maintenance is required.

-

No need to regularly lubricate or grease the clamping unit.

-

No regular complete cleaning is required.

-

Longer operational life.

-

High accuracy and precision.

-

Better distribution of clamping force.

-

Better control over clamping unit pressure and speed settings.

-

Stable clamping pressure.

-

Fast and smooth clamping unit operation.

-

Increased mould safety.

Designed for high stability and reliability, all the machines are designed with four tie-rod style clamping unit for stable and vibration-free clamping unit movement, four tie-rods provide high structural strength and smooth operation.

Ram type clamping unit combined with four tie-rod type clamping unit, translates to a better distribution of clamping force over the mould, providing a better moulding result.

_edited.png)

DIVERESE INJECTION UNIT

The injection is the only way to control material flow inside the mould thus higher control over material flow and injection position is required to achieve high-quality moulded components.

With a highly customizable injection unit you can choose the injection unit that suits your production requirements.

Using an accurate measuring apparatus and highly sensitive controller we can accurately control the positioning of injection to control the exact amount of material entering the mould thus producing the best moulding results and these results can be reproduced an infinite number of times.

The Hydraulic injection system is highly reliable and robust with our optional bimetallic screw injection unit and can be taken to next level of usage with high-density materials.

Multiple Heating Zones provide accurate control over the material melting process inside the barrel, you can set custom heating stages for materials and melt the material accurately resulting in reduced time material has to stay at higher temperatures thus preserving material composition and integrity.

Multiple Injection Unit Screw Options depending on your production requirement you can choose your ideal injection unit.

FAST AND PRECISE ROTARY TABLE

Equipped with a 3 station type rotary table that has 3 stopping positions one inside the clamping area, 1 at the ejection station and 1 at the insert placement station, utilizing 3 bottom half of moulds and 1 top half of mould.

When the operation cycle starts there is one mould inside the clamping area and the process of moulding is going on, 2nd bottom half of the mould is at the ejection station 120 degrees from the clamping station, where one operator is located and removes the finished moulded components from the mould and prepares the mould for insert placement at 3rd station, at 3rd station there is another operator who places inserts inside the mould and when the moulding process at stations is completed then the operators start the next cycle and the rotary table rotates 120 degrees and the whole process starts again. completing total 360 degree table rotation movement.

The rotary table is electronically controlled by a servo motor on an absolute encoder system that makes sure that the rotary table movement is accurate and fast, reducing the chances of mould misalignment and mould damage to zero, the rotary control system tracks the rotation movement to 0.1 degree accuracy. with soft start and soft stop making the table super accurate and fast.

3 STATION / 2 STATION

Rotary 3 station-type vertical injection moulding machines can also be operated in two-station mould transfer mode.

In 2-station transfer mode, the machine operates just like a normal rotary mould rotating only 180 degrees in and out of the clamping area, this helps with compatibility when there is only 1 & a half mould available or only a single mould is available.

Switching the machine to 2 stations is simple, After switching to 2 station mode the machine can work with 2 stations or 1 station operation mode, supporting both 1 & half moulds and 1 single mould.

_edited.png)

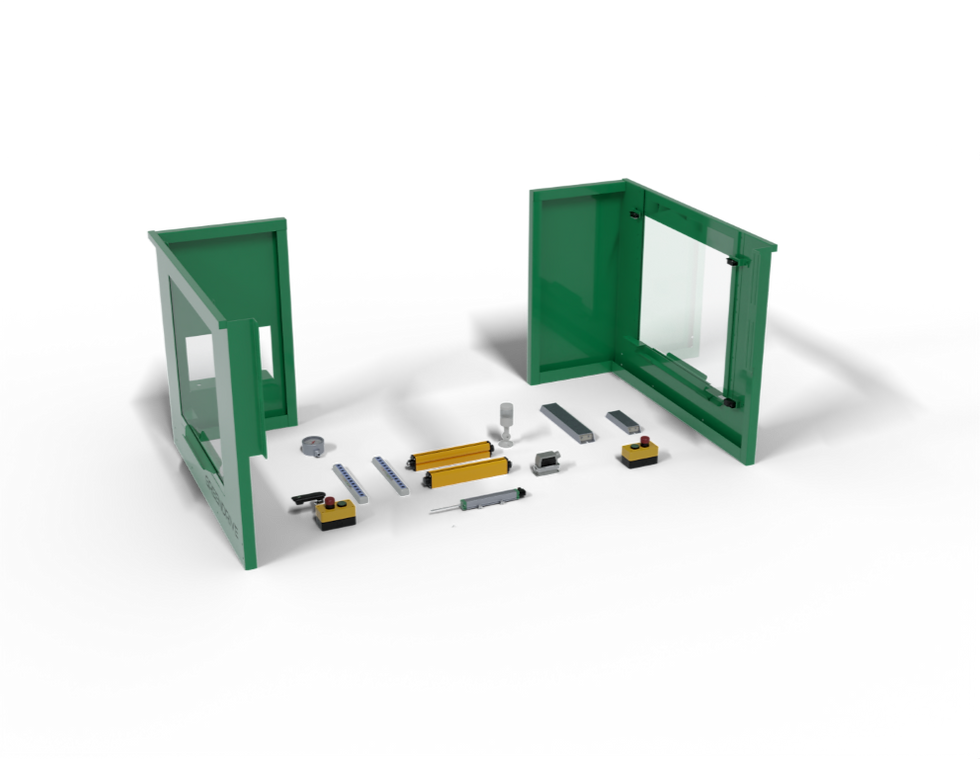

SAFETY IS HIGHEST PRIORITY

When operating machines that are designed to operate at high temperatures and pressure, safety should be the highest priority, with our machines safety is a core part of the design as we have integrated multiple safety features in our machines to reduce the number of accidents to zero.

Equipped with multiple safety devices such as.

-

Safety light curtains

-

Side safety doors

-

Emergency switches

-

mechanical pressure indicators

-

electrical redundancies

-

electrical safety

-

emergency light with buzzer

-

mechanical safety for mould and machine safety.

All safety devices work together to create a safe operating experience for the operator, reducing the chance of accidents to almost zero.

.png)

CONTROLLER

All our machines come equipped with LNC controller as standard.

LNC controllers are best in the segment, they provide a high level of control and precision and advanced features that many controllers in this segment can not provide.

We have two controllers depending on the machine model that you choose

In5800 - LNC controller with an 8-inch HMI display and similar performance to the other higher-end LNC controller.

In6800 - LNC controller with a 10-inch HMI display, high-end features, and top of the line performance.

Both controllers have advanced features for machine control and user inputs while being user-friendly and easy to operate.

Equipped with features like remote diagnostics for problem resolutions, EUROMAP configuration, remote monitoring, inter-machine data compatibility, customizable functions, easier integration for automation devices such as robots, Easier integration of industry 4.0 technology, and much more.

We also provide other controllers depending on our customer's requirements but we recommend LNC controllers with our machines over all other controllers.

MACHINE OPERATION

-

CYCLE START

-

ROTATE TABLE 120°

-

MOULD CLOSE

-

MOULD SAFETY STAGE

-

CLAMPING

-

INJECTION

-

COOLING START

-

PLASTICIZING

-

SUCKBACK

-

COOLING STOP

-

CLAMPING RELEASE

-

MOULD OPEN

-

ROTATE TABLE 120°

-

EJECTION

MACHINE PHOTOS

SUPPORT FOR ROTARY 3 STATION TYPE MACHINES

Looking for resources or support for a rotary 3 station type vertical injection moulding machine, visit our support page for all the resources.